- #BUSINESS PROCESS MODELLING FOR RETURNS EXAMPLES DRIVER#

- #BUSINESS PROCESS MODELLING FOR RETURNS EXAMPLES SOFTWARE#

With software organizations can easily create and run a process model to identify areas for improvement.Īs written in a previous blog post, business process mapping techniques, “you can’t manage what you don’t measure.” Business process modeling vs business process mapping This method is, however, far more time-consuming, and less effective than leveraging an automation solution like business process modeling software. It is possible to manually sketch out the steps in a process. The second is what the process will be once improvements have been made. The first is the process as it currently exists without implementing any changes. It does this by mapping two different iterations of a given process.

Next, business process modeling is used to identify improvements in an organization’s business processes or workflows.

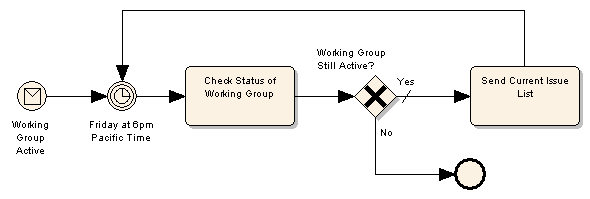

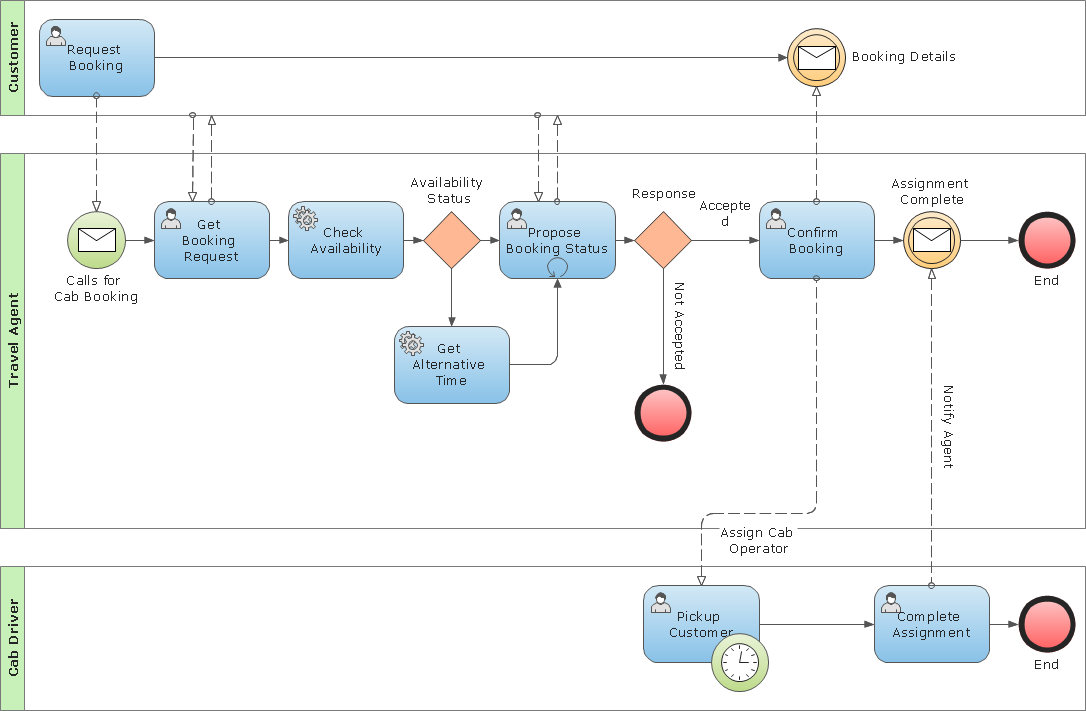

This is typically achieved by using business process modeling tools like flowcharts and universal business modeling process notation (also known as BPMN). What is business process modeling?īusiness process modeling is a technique that involves creating a visual depiction of a business process. In this post, we explain how business process modeling techniques give you the knowledge to improve performance across your enterprise. It allows the creator to visualize a more efficient process. Business process modeling is a tool that organizations use to evaluate their current processes. This work closes part of the gap between the support for administrative processes and physical industrial processes, thus contributing to the advent of the smart manufacturing concept in the context of Industry 4.0.Great organizations continually improve their processes over time, striving to make them as efficient and cost-effective as possible. The results show strong support for the use of business process models for both representation and enactment of manufacturing processes. We demonstrate the use of our catalogue of fragments by modelling and enacting the real-world processes of ten manufacturing organizations. We use the industry standard Business Process Model and Notation (BPMN) to represent both fragments and processes. These process fragments serve as reusable building blocks for the specification of manufacturing processes. Our approach is based on a catalogue of common process fragments that are adapted to the physical nature of manufacturing. In this paper, we present an approach to use business process models for the specification of these physical operations processes. These processes have physical characteristics that make them essentially different from administrative processes with a highly digital nature, like limited physical buffers for intermediate products and transportation times between activities.

However, business process modelling remains unproven for all the processes encountered in manufacturing enterprises, including the physical operations processes that transform input materials into the required product. Business process modelling as part of BPM has shown its potential in administrative environments, such as banking and insurance organizations.

#BUSINESS PROCESS MODELLING FOR RETURNS EXAMPLES DRIVER#

Business process management (BPM) is often employed as a driver of integration, by articulating business processes that cross the boundaries of individual business functions.

0 kommentar(er)

0 kommentar(er)